When a vehicle is in motion, every component works together to ensure safety, control, and performance—but few parts are as critical as the braking system. At the heart of that system lies the brake disc, a component responsible for converting motion into controlled stopping power. Whether it’s a compact passenger car navigating city streets or a heavy-duty truck hauling tons of cargo across highways, the quality of the brake disc can make the difference between smooth operation and serious risk. This is why choosing a reliable brake disc manufacturer is essential for both everyday drivers and commercial fleet operators.

The Role of Brake Discs in Modern Vehicles

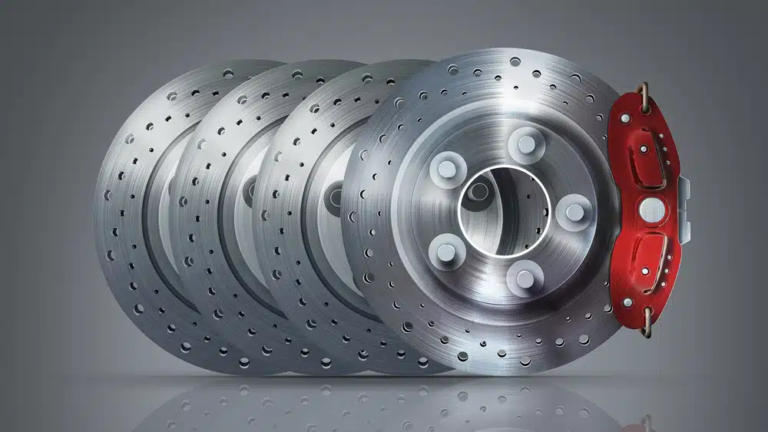

Brake discs, also known as rotors, work in coordination with brake pads and calipers to slow down or stop a vehicle. When the brake pedal is pressed, the pads clamp onto the disc, generating friction that reduces wheel rotation. This process produces intense heat and pressure, especially in heavy-duty vehicles that operate under high loads.

A professional brake disc manufacturer designs products that can withstand extreme temperatures, resist wear, and maintain consistent performance over time. Poorly manufactured discs may warp, crack, or fade under stress, compromising safety and increasing maintenance costs.

Passenger Vehicle Brake Discs: Precision and Comfort

Passenger vehicles require brake discs that balance performance with comfort. Noise reduction, smooth braking, and long service life are major priorities. A high-quality brake disc manufacturer focuses on precise machining and material selection to deliver rotors that perform quietly and efficiently.

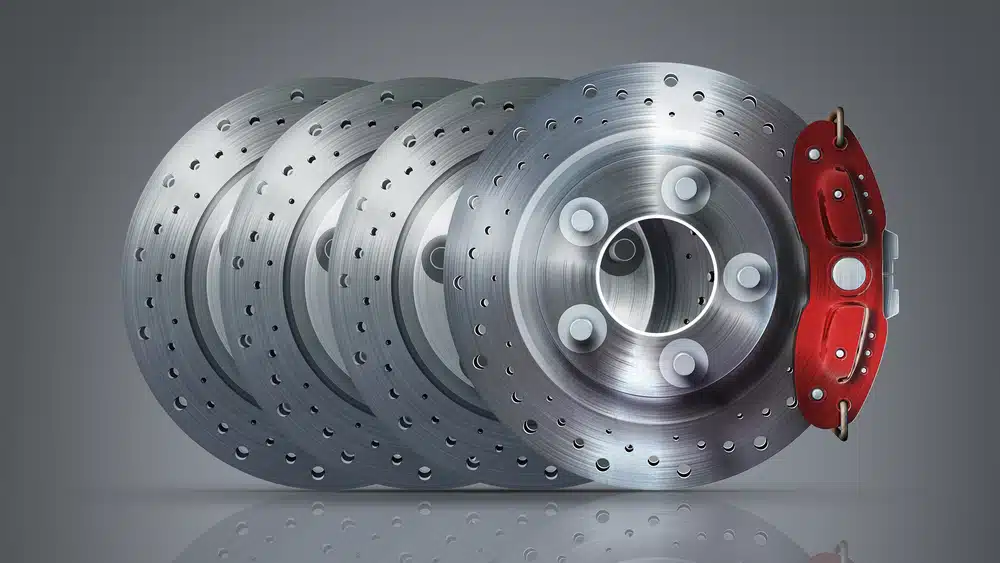

Cast iron alloys are commonly used for passenger car brake discs because they offer excellent heat dissipation and durability. Advanced manufacturers also apply special coatings to protect against corrosion, especially in regions with high humidity or winter road salt. These innovations help ensure that braking remains consistent, even after years of daily driving.

Heavy-Duty Vehicle Brake Discs: Strength Under Pressure

Heavy-duty vehicles such as buses, trucks, and construction equipment place enormous demands on their braking systems. These vehicles carry heavy loads, operate for long hours, and often travel through challenging terrain. As a result, their brake discs must be significantly stronger and more resistant to thermal stress.

A specialized brake disc manufacturer for heavy-duty vehicles uses reinforced materials, thicker disc designs, and advanced casting techniques to handle extreme operating conditions. Ventilated and high-mass rotors are often employed to improve heat dissipation and reduce the risk of brake fade during prolonged use.

Manufacturing Process: Where Quality Begins

The difference between an average product and a premium one lies in the manufacturing process. A trusted brake disc manufacturer follows strict quality control standards at every stage—from raw material inspection to final testing.

The process typically begins with high-grade metal casting, followed by precision machining to achieve exact dimensions and balance. Computer-controlled equipment ensures uniform thickness and smooth surfaces, which are essential for vibration-free braking. After machining, discs are tested for hardness, thermal stability, and structural integrity.

Leading manufacturers also comply with international quality standards such as ISO, SAE, and OEM specifications. These certifications provide assurance that the brake discs meet global safety and performance requirements.

Innovation and Technology in Brake Disc Manufacturing

As automotive technology evolves, so does brake disc design. Modern vehicles demand lighter, more efficient, and environmentally friendly components. Forward-thinking brake disc manufacturers invest in research and development to meet these changing needs.

Innovations such as high-carbon brake discs improve heat resistance and reduce noise, while composite and coated rotors enhance durability and corrosion protection. Some manufacturers are also exploring eco-friendly production methods to reduce emissions and energy consumption during manufacturing.

For electric and hybrid vehicles, braking systems must adapt to regenerative braking technologies. This requires brake discs that perform reliably even when used less frequently but under sudden, high-demand situations.

Why Choosing the Right Brake Disc Manufacturer Matters

Selecting the right brake disc manufacturer is not just about cost—it’s about long-term safety, reliability, and performance. Inferior brake discs can lead to uneven wear, reduced braking efficiency, and increased downtime, especially in commercial fleets.

A reputable manufacturer provides consistent quality, technical support, and the ability to customize products for specific vehicle models or operating conditions. This is particularly important for fleet operators who rely on predictable maintenance schedules and minimal vehicle downtime.

Global Supply and Aftermarket Support

Today’s automotive industry is global, and a capable brake disc manufacturer serves both OEM and aftermarket clients worldwide. Efficient logistics, reliable supply chains, and responsive customer service are key factors that set leading manufacturers apart.

In the aftermarket sector, compatibility and ease of installation are crucial. Manufacturers that provide detailed specifications, proper packaging, and clear documentation help mechanics and distributors ensure correct fitment and optimal performance.

The Future of Brake Disc Manufacturing

The future of brake disc manufacturing will be shaped by advancements in vehicle technology, stricter safety regulations, and growing environmental awareness. Manufacturers that prioritize innovation, quality, and sustainability will continue to lead the market.

From passenger cars to heavy-duty vehicles, brake discs will remain a vital safety component. Partnering with an experienced and forward-looking brake disc manufacturer ensures that vehicles are equipped to stop safely, efficiently, and reliably—no matter the road ahead.

In a world where performance and safety cannot be compromised, the importance of a trusted brake disc manufacturer stands stronger than ever.